SonicCPT is an exciting and rapidly developing technique from Royal Eijkelkamp that is reducing early refusals in CPT soundings by carefully applying a vibration, when needed, to the CPT string. The technique actually has a history dating back almost 40 years to when Sasaki et al. (1983) reported their work to develop and deploy their vibratory cone, which they used for liquefaction analysis. They compared tip resistance with and without vibration and found that in loose soils the tip resistance was substantially lower in vibratory mode due to the additional excess pore pressure generated, whereas in stiff soils the vibration did not create additional excess pore pressure and the tip resistance was similar.

Royal Eijkelkamp’s expertise in sonic drilling technology has allowed us to take this pioneering work much further and develop into three key areas of application.

The first application is to deal with layers of very hard soil above or between layers of softer material. With conventional CPT it is impossible to push through these layers and the test must be terminated. Sometimes destructive drilling will be performed which is costly and doesn’t provide data. However, with the SonicCPT it is often possible to use the vibratory action to penetrate the hard layer, after which standard CPT pushing can be continued in the softer material below.

Secondly, by applying vibration to the CPT rod string, friction between the rods and soil is largely eliminated. This allows for a higher percentage of the pushing force to be transferred to the cone, so the cone can then be pushed deeper into the soil. This is particularly useful in stiff cohesive material, such as London Clay where almost one tonne of pushing force per meter can be required to overcome rod friction. This can also improve the applicability of lower weight CPT rigs, which provide a smaller reaction force.

The third application is when producing pile driving simulations for vibratory hammer piling. Standard CPT data has long provided excellent input for impact hammer pile driving simulations, but is less suitable for piling using a vibratory hammer. With SonicCPT we can approach or even match the frequency of a vibratory hammer to test the influence of the vibrations on the soil.

When equipped with an Eijkelkamp SonicCPT system, the user can just push the CPT into ground without vibration, as per a normal CPT. When the vibratory action is required the cone is still advanced at a speed of 20 mm/s (as per a normal CPT), while vibrating the cone at a frequency between 30 and 150 Hz, although normally below 100 Hz.

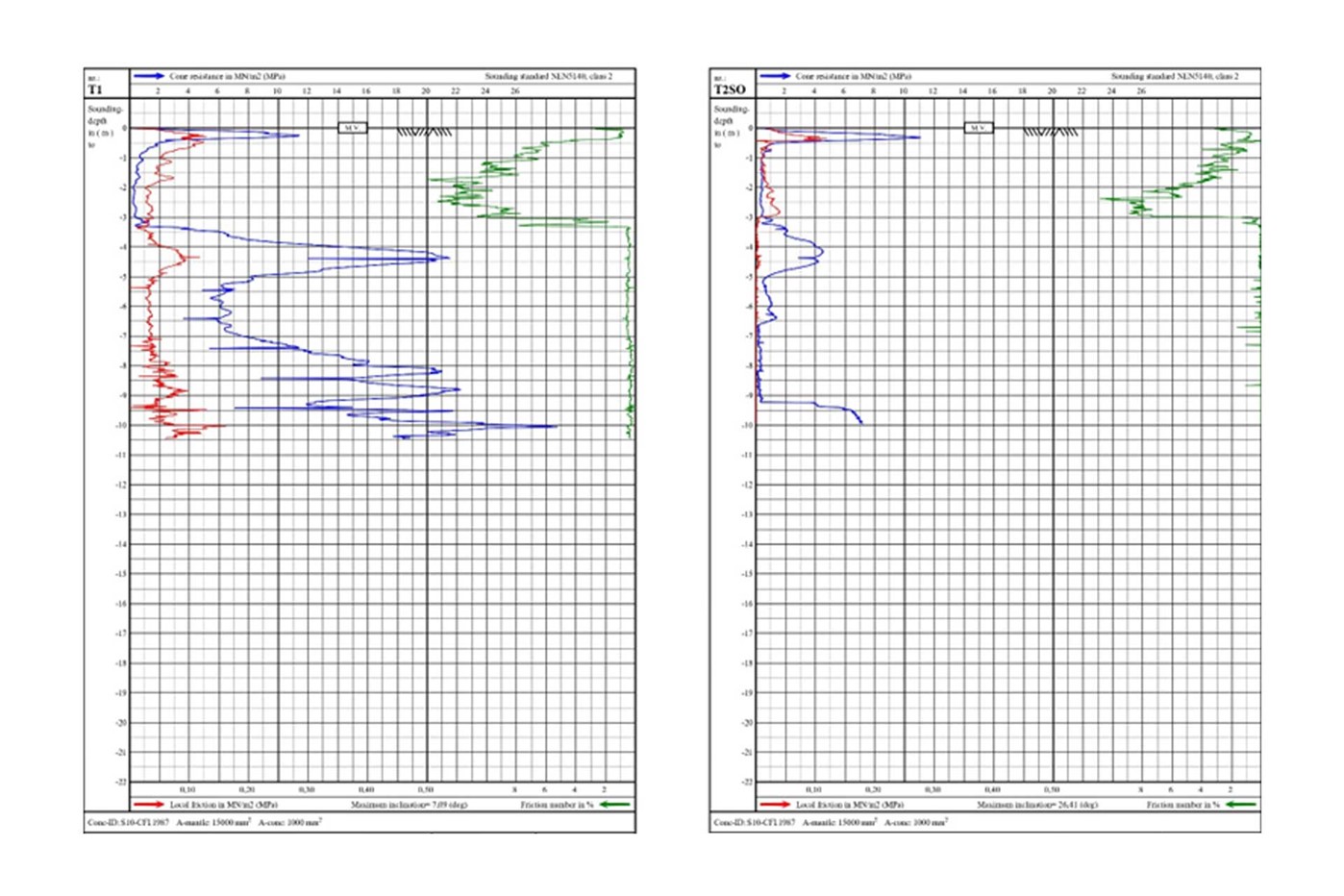

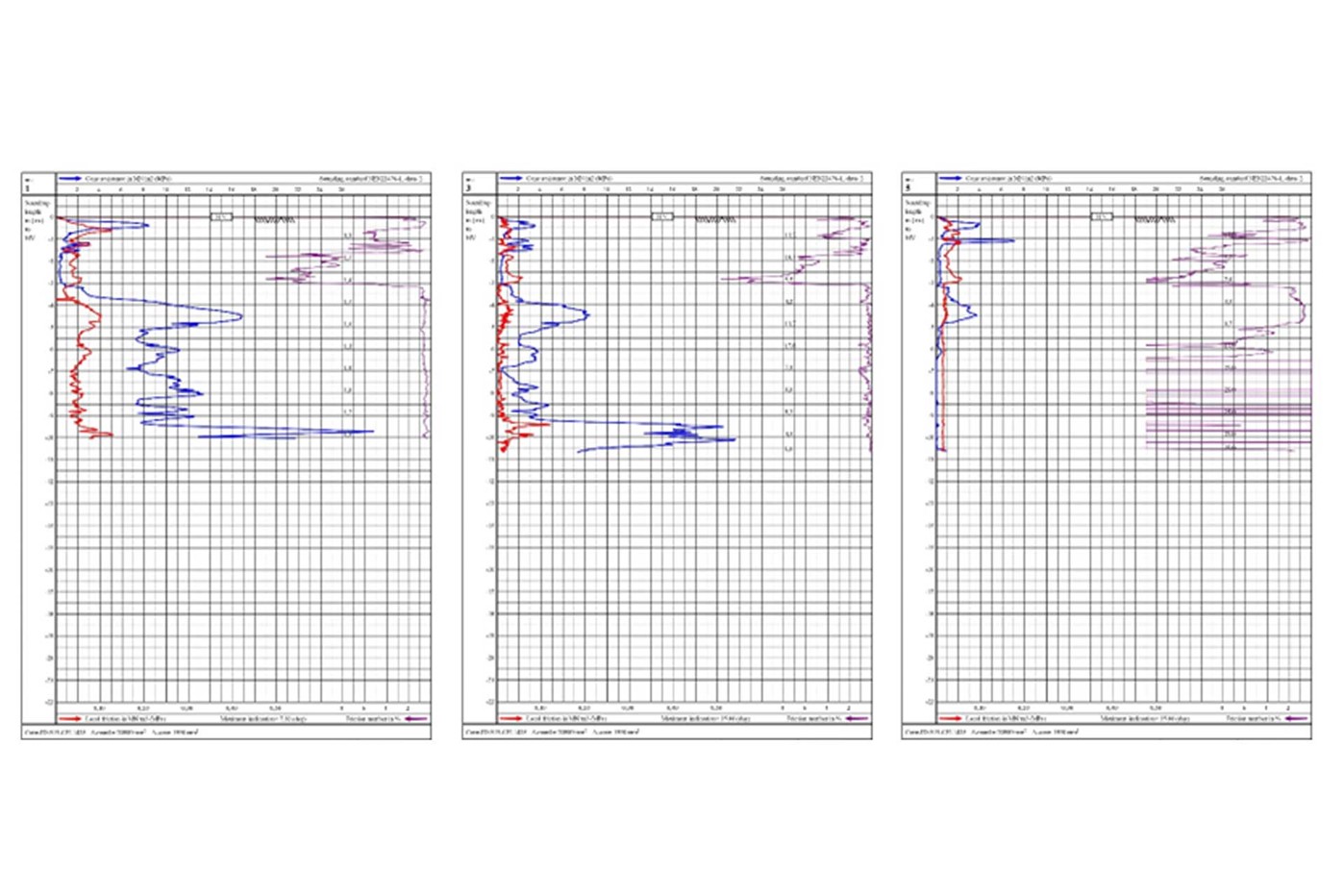

Testing performed so far shows that the frequency used has a large impact on the resultant data. As shown in Figure 2 in the examples below, vibrating the cone at 100 Hz greatly reduces the resultant tip resistance, meaning the cone can penetrate harder layers more easily, but the profile does not reflect the profile of the standard CPT.

However, as shown in Figure 3, when the frequency is reduced to 50 Hz the shape of the profile resembles the profile of the standard CPT and is therefore more instructive of the soil conditions.

Figure 2: Comparison of Standard CPT and SonicCPT (100 Hz)

Figure 3: Comparison of Standard CPT and SonicCPT (50 Hz and 100 Hz)

SonicCPT is a developing technology that has several real-world applications. This includes potentially increasing the penetration depth of standard CPT, for example under the following criteria:

Despite the roots of SonicCPT dating back to 1983, the modern application of the technique is relatively new and therefore is very much a developing technology. This means that several aspects of SonicCPT are still under rigorous testing and development by Eijkelkamp.

For example, when standard CPT is performed and refusal occurs in a soft rock layer, additional testing is required to establish the operational practice to best deal with such a situation as well as to establish the strengths and thicknesses of soft rock that can be penetrated.

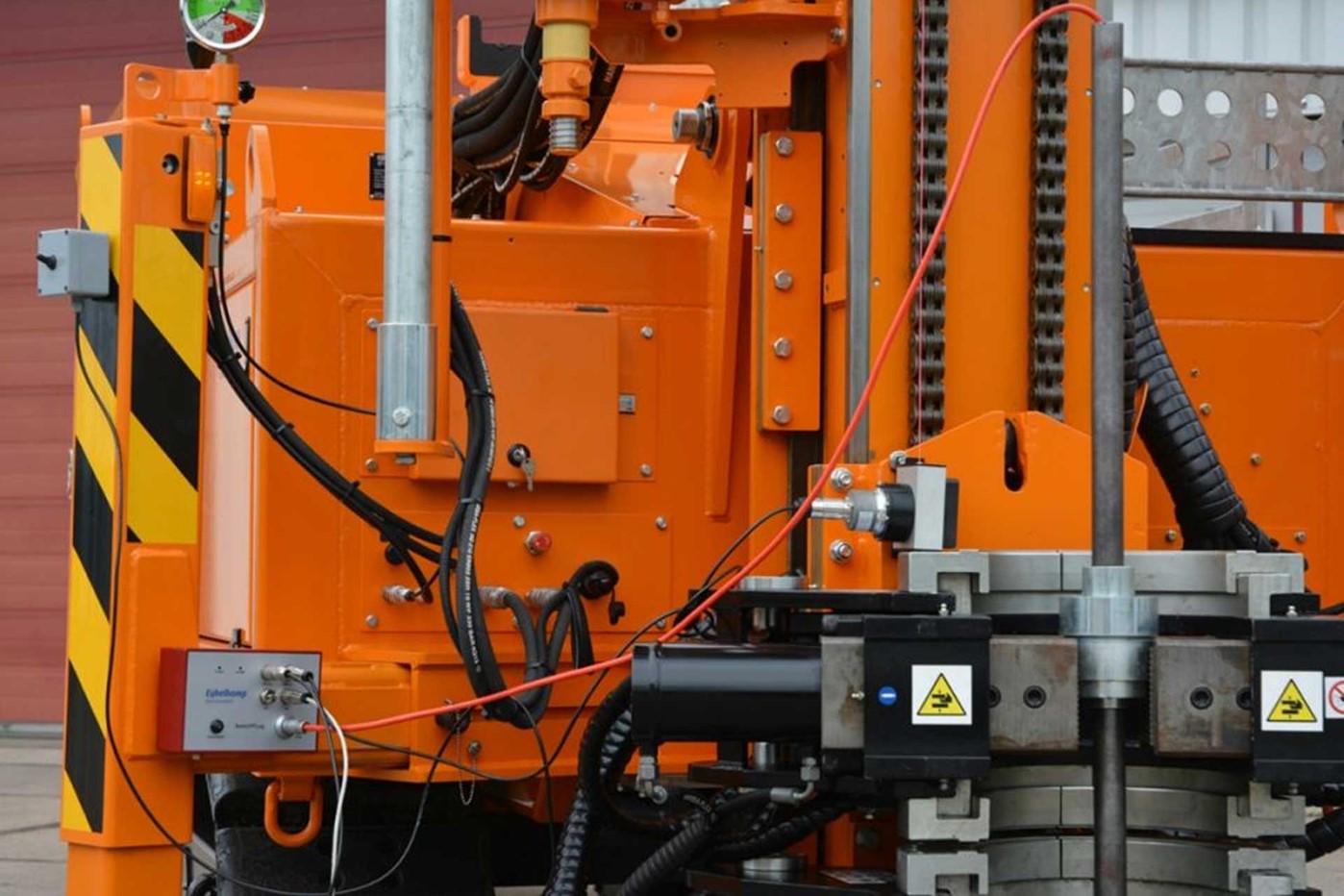

Figure 1: Rig with sonic CPT push head

To determine how the data obtained with SonicCPT can be best applied to simulate vibratory pile driving additional testing and research is also required.

The proportional reduction of the cone resistance under the application of the SonicCPT is tied not only to the operating frequency, but also to the properties of the soil, in particular the soil’s response under vibration. This makes the SonicCPT an exciting technology to determine the soil liquefaction potential, but once again more research is required into this application.

While SonicCPT can only be used to determine the cone resistance and the sleeve friction, Royal Eijkelkamp is currently working on the development of piezocones that can be used for SonicCPT.

When standard CPT is performed and refusal occurs while the force on the cone tip is substantially lower than the pusher’s rated force, a brief application of SonicCPT may resolve the refusal condition.

When standard CPT is performed and refusal occurs in a relatively thin, but very stiff soil layer, SonicCPT can be applied to penetrate that stiff layer, before standard CPT is continued.

When standard CPT is performed and refusal occurs in a soft rock layer, additional testing is required to establish the parameters to best deal with such a situation as well as to establish the soft rock layers that can be penetrated.

To determine how the data obtained with SonicCPT can be best applied to simulate vibratory pile driving, additional testing and research is also required.

Currently testing is ongoing to enhance Royal Eijkelkamp’s understanding of SonicCPT, so we can provide our clients with a tool to supplement the standard CPT soil investigation technique.

Royal Eijkelkamp is a provider of a full range of Cone Penetration equipment: mechanical, electrical and SonicCPT. Feel free to contact our CPT specialists with your questions.