Focusing on the safety of your crew does not just mean fewer injuries; it also makes financial sense. That’s why we adhere to the motto: “Safety isn’t expensive, its priceless!” Yes, next to the standard PPE hat drillers and assistants need to wear, there are also standards for safety for machinery used in the drilling industry. But our machines are designed to be even more safe and ergonomic than these safety standards. If you ask us, these are the safety features that every Sonic rig needs.

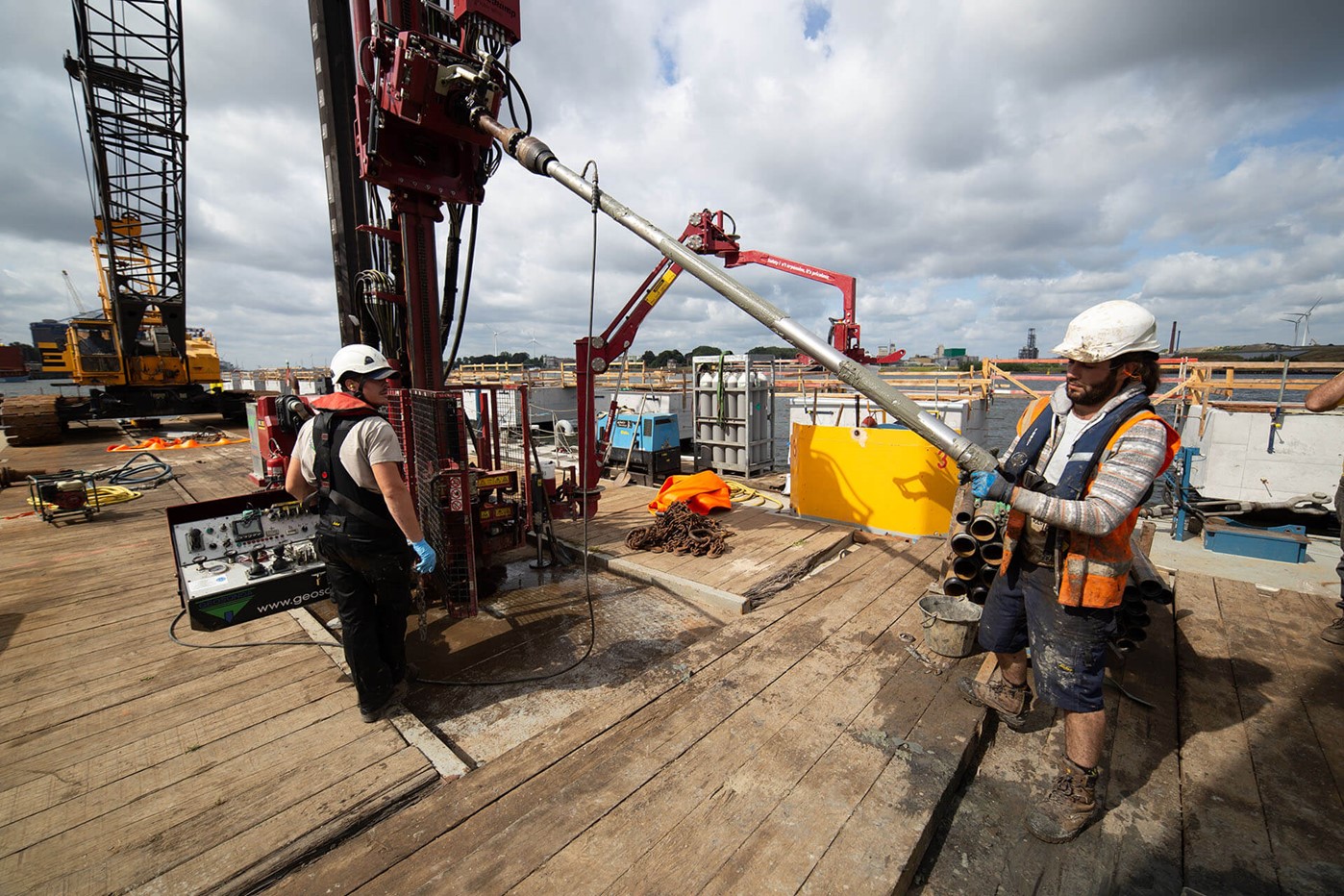

Drilling can be a dangerous job. After all, there’s a sonic drill head rotating at high speed and moving up and down the mast, heavy rods and casings vibrate with 150 Hz and need to be lifted around the rig. The crew is in danger of getting clothing caught in moving parts, body parts crushed or pinched and backs and shoulders injured. The more injuries that can be prevented, the better! The features listed below are standard or optional for all our Sonic rigs.

Safety cage

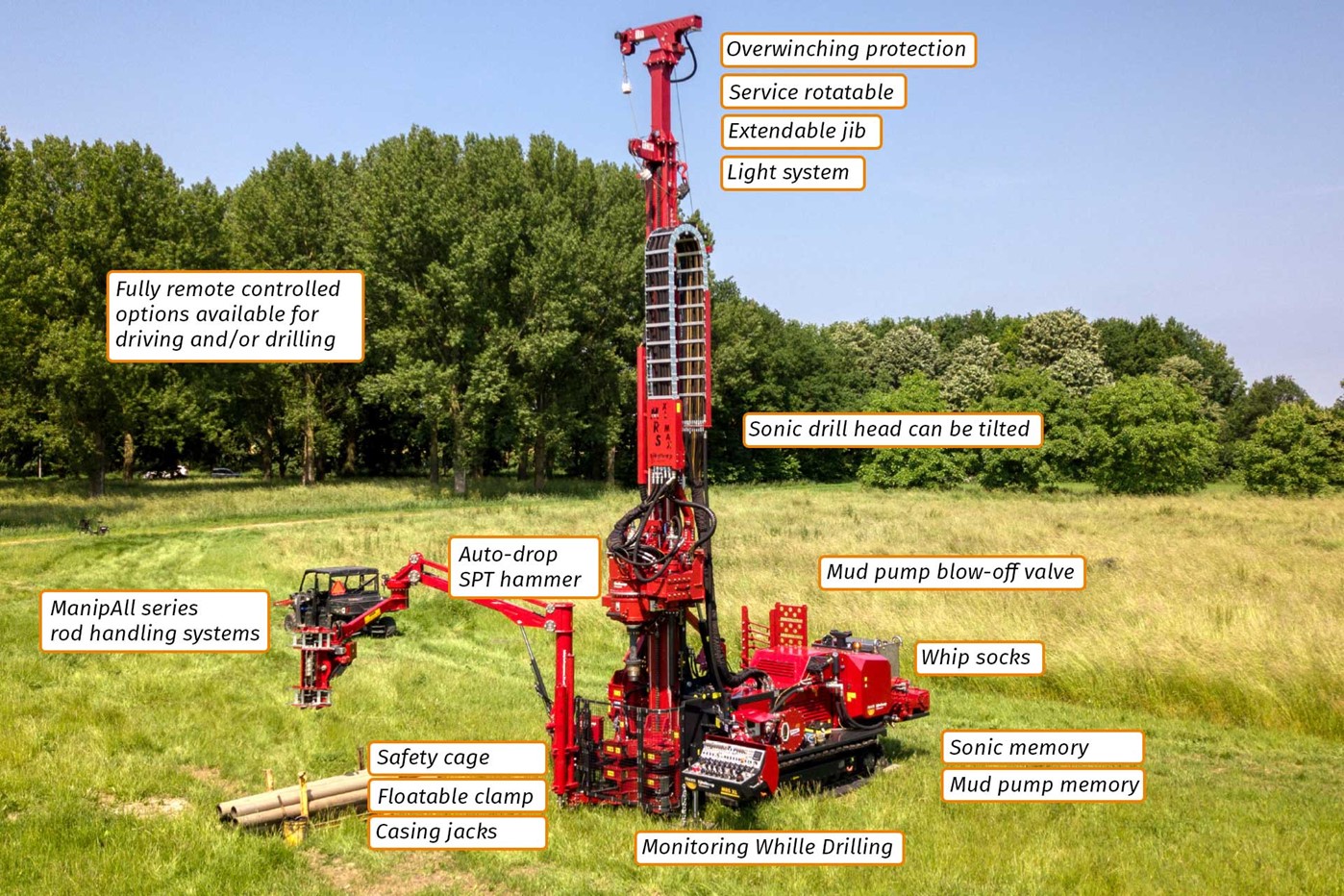

So let’s start with a safety feature that actually is required by industry standards in Europe by EN 16228. The safety cage is a standard feature on all Royal Eijkelkamp rigs. It closes around the drill head and rotating tooling for complete protection of the sonic head and clamps area to keep tools, body parts, and clothing out of harm’s way.

In fact, the rig has an emergency shut-off feature that is activated when the cage door is opened. All drilling activity is immediately shut down. Coloured lights indicate whether the cage is open or closed.

To protect the backs, arms and fingers of drill operators, Royal Eijkelkamp rigs can be equipped with various means to automate the handling of tooling and make lifting easier.

The ManipAll rod handler

The Royal Eijkelkamp ManipAll arm helps pick up and lift rods or casings, and can be operated by a single drilling assistant. It lifts the tooling quickly and easily to a vertical position and swings it into place under the drill head. The ManipAll is equipped with either clamps or industrial magnets to grab tooling, and it can be safely operated by hand or optional remote control.

This arm adds efficiency in addition to safety. For example, while the driller is busy drilling with the current tooling, the assistant can get the next piece into position.

It also saves you the step of off-loading and staging your tooling – the ManipAll can pick up rods and casing right from your rig, truck, or rack. In addition, the ManipAll adds very little to a rig’s footprint, and it can be mounted on any drill rig – not just a Royal Eijkelkamp rig.

Automatic manipulator rod handler

The automatic manipulator helps to handle rods more safely by picking up a drill pipe from the rig’s on-board rack and safely lifting it up parallel to the drill head. The head shifts over, connects the flange adapter to the drill rod’s thread and then shifts back to the centre of the borehole to continue drilling. The manipulator can be safely operated from the driller’s control panel, with several automated features including rod separators, strong gripping pliers, and a bottom rod guide that ensures perfect alignment. Operators don’t need to touch the drill pipes and are not at risk of becoming fatigued due to the lifting.

Floatable break-out clamps

For automatic breaking of the threaded tooling joints, break-out clamps are mounted at the bottom of the drill mast.

The driller can remotely clamp casings and rods and then control the drill head to release joints quickly and safely. No wrenches required! An optional floating clamp helps break the rods at various heights.

Winch

The rotatable and extendable jib with wireline winch helps with heavy lifting around the borehole. This could be for heavy auxiliary materials, or drill rods and casing pipes. Some machines even have a second winch. To protect the winch from overload or failure, this feature comes with over-winching protection.

Casing jacks

The casing jacks help to pull up casings in a safe way, with a 300 mm stroke and pulling force of 10,000 to 20,000 daN.

Auto-drop SPT hammer

The auto-drop SPT hammer provides a fully automatic, dynamic and hydraulically liftable penetrometer for SPT probes. It is mounted on a side sliding guide alongside the drilling mast.

Tilt on the sonic drill head

The sonic drill head can be tilted horizontally for safe and easy extraction of the sample.

All drilling functions can be performed with the remote control, apart from levelling the rig and setting up the mast which needs to be done from the fixed control panel. We’ve positioned the fixed control panel so that even when you move it around the rig, you’ll maintain sight of the moving parts.

The remote controlled drilling functions let you operate the machine from a safe distance whilst keeping an eye on the borehole. You can move and position the machine while keeping a safe distance. We’ve also incorporated a buzzer, that will sound to alert bystanders when the rig starts to move.

Our Sonic machines have a built-in memory function for sonic and mud pump. You’ll be able to easily load a preset Sonic frequency for convenient, safe and efficient drilling. The memory on the mud pump offers preset pressures and flows.

To keep the working environment safe and prevent hoses from flying around or air and liquids escaping, the rigs can be equipped with additional safety systems where necessary.

For example, to protect the drilling area from a high-pressure release of flushing liquid, the mud pump is equipped with a blow-off valve. Whip socks help keep hoses safely in position, even when a hose is leaking or the connection breaks. An integrated light system keeps drilling operations safe and visible, even at night time. And finally, all hydraulic cylinders are equipped with load-holding valves so that even when hydraulic pressure is lost, the valve will keep the cylinder and its load firmly in position.

Over the last decade, safety has become more and more essential and a prominent factor in drilling and mining. It is not just about safety vests, hats, and eyewear – a focus on safety in equipment design and how drillers operate that equipment has led to significant improvements.

Our high standards make the Royal Eijkelkamp sonic drill rigs safer and more ergonomic than the industry requirements. But more than that, these features designed for safety also help to boost efficiency and productivity for your projects.